Product Description:

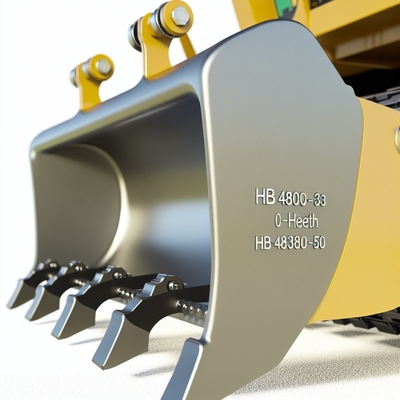

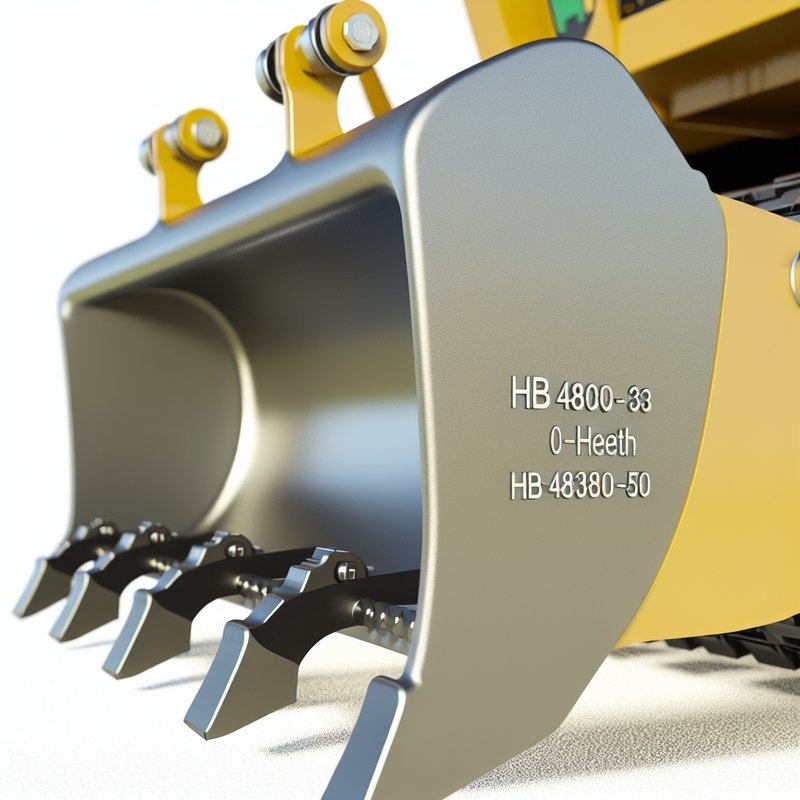

When it comes to reliable and durable excavator ripper bucket teeth, look no further than our top-of-the-line product offering. Designed to withstand the toughest conditions, our excavator ripper bucket teeth are a must-have for any digging project.

With a hardness ranging from $3 to $5, our excavator ripper bucket teeth are built to last. The bucket tooth hardness falls within the range of HB 480-530, ensuring superior strength and wear resistance even in the most challenging environments.

Whether you are working on a construction site, mining operation, or any other excavation project, our excavator ripper bucket teeth are up to the task. Their durability and reliability make them an essential tool for efficient digging and material handling.

With a HS code of 8431499900, our excavator ripper bucket teeth are easily identifiable for shipping and customs clearance, streamlining the procurement process for our valued customers.

For added convenience and protection during transportation, our excavator ripper bucket teeth are carefully packed in sturdy wooden cases. This ensures that the product reaches you in pristine condition, ready to tackle any digging job with ease.

Although we do not offer local service locations, our customer service team is always available to assist you with any inquiries or support you may need regarding our excavator ripper bucket teeth. Your satisfaction and success with our products are our top priorities.

Don't settle for subpar excavator teeth when you can equip your machinery with our high-quality excavator ripper bucket teeth. Trust in our product to deliver exceptional performance, longevity, and efficiency for all your digging needs.

Features:

-

Product Name: Excavator Bucket Teeth

-

Excavator Brand: Komatsu

-

Packing: Wooden Case

-

Usage: Excavator Bucket

-

Bucket Tooth Hardness: HB 480-530

-

Description: Left Corner Tip

Technical Parameters:

|

Local Service Location

|

None

|

|

Description

|

Left Corner Tip

|

|

Payment Term

|

30% Downpayment,70% Before Shipment

|

|

Usage

|

Excavator Bucket

|

|

Adapter

|

2713-1218

|

|

Width

|

Standard

|

|

Dimension

|

Standard

|

|

Hs Code

|

8431499900

|

|

Hardness

|

$3-$5

|

|

Excavator Brand

|

Komatsu

|

Applications:

Excavator bucket teeth are essential components for excavator digger buckets, providing the necessary cutting and digging capability for various applications. The Excavator Bucket Teeth product with the adapter 2713-1218 is a high-quality option suitable for heavy-duty usage in a range of scenarios.

These excavator bucket teeth are designed with a hardness level between $3 to $5, ensuring durability and wear resistance during demanding digging tasks. The standard width of the teeth allows for compatibility with different bucket sizes, offering versatility in various excavation projects.

With an elongation rate of at least 4%, these bucket teeth exhibit excellent flexibility and toughness, reducing the risk of breakage or deformation under intense pressure. The product is classified under HS Code 8431499900, meeting industry standards for quality and performance.

The excavator bucket tooth adapter included in this product package, model 2713-1218, enhances the overall stability and strength of the teeth when attached to the bucket, ensuring secure operation even in challenging environments. Whether used in construction sites, mining operations, or landscaping projects, these excavator heavy-duty bucket teeth provide reliable performance and efficiency.

From digging trenches and excavating foundations to handling rocky terrains and scooping materials, the Excavator Bucket Teeth with the 2713-1218 adapter offer a versatile solution for a wide range of excavation tasks. Their robust construction, optimal hardness level, and standardized width make them ideal for heavy-duty applications that require dependable cutting and digging capabilities.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!